Since the company's founding, technical advances in constructions, yarns, and materials have helped Faytex become a global leader in fabric design and development..

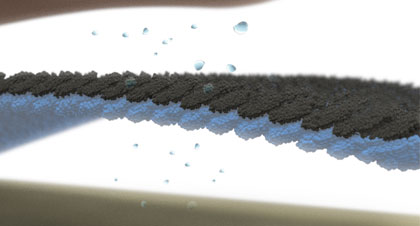

Simulation of perspiration through Dri-Lex fabric

DRI-LEX®

Most Dri-Lex® fabrics are engineered specifically for footwear applications. A range of technical textile structures and high performance fibers give Dri-Lex® excellent moisture movement properties as well as outstanding abrasion resistance, hand-feel, and attractive patterns and textures. A wide range of Dri-Lex® fabrics also provide additional visual appeal through thermal transfer print patterns.

How it works

In footwear applications, perspiration is moved away from the foot surface by heat and mass transfer and into the specific Dri-Lex® fabric in the lining, footbed or upper. The fabric then works in conjunction with other materials to re-distribute moisture. The most advanced technical textile structures in the Dri-Lex® product line are the Dri-Lex® Diffusion products.

Dri-Lex® Aerospacer

Dri-Lex® Aerospacer is a patented three-dimensional composite structure of hydrophobic and hydrophilic layers separated by an air chamber.

Its design allows air to circulate and dry the foot while moisture is delivered to the outer layer of the shoe upper and subsequently air-dried.

AEGIS MICROBE SHIELD

AEGIS Microbe Shield is a fabric treatment that combats odor -causing bacteria by means of a physical mechanism.

Each of the three sections of the AEGIS® molecule have specific roles: the long carbon chain interacts with odor-causing bacteria cell walls; positively charged nitrogen disrupts ionic balance and punctures the bacteria cell walls; and a siloxane group binds it to the fabric surface. Simply stated, Aegis punctures the cell walls of odor-causing bacteria destroying them in the process.

In addition to its odor-fighting properties, AEGIS® is chemically bound to the fabric surface and does not migrate into the environment.

DRI-LEX ECO™

In today's footwear marketplace, environmentally friendly fabrics are taking center stage with consumers.

To meet this demand, we have developed an entire collection of fabrics offering a wide range of fibers with low environmental impact. Under the 'Dri-Lex Eco™' banner, fabrics containing these fibers may be made with renewable content featuring DuPont Sorona® or recycled content featuring Repreve® polyester or nylon (polyamide).

Dupont SORONA® sustainable fibers

DuPont has created a new category of polymer called triexta. Its characteristics include a full, soft hand and higher elasticity than common polyester. Marketed under the trade name 'Sorona,' these fibers contain 37% non-petroleum derived chemicals obtained through the fermentation of renewable — and sustainable -- plant sugars.

Sorona® exists in the sweet spot where performance and sustainability intersect.

Performance features of Sorona® fiber include:

Superior tensile strength;

Stretch and 100% recovery;

Exceptional softness;

Can be dyed at lower temperatures, saving energy.

DuPont Sorona is exclusive to Faytex for the footwear category.

Repreve® recycled polyester from Unifi, Inc.

Repreve® recycled fibers in Dri-Lex Eco fabrics offer distinct advantages to you and your consumers that are easily understood:

- They are initially certified as recycled and can be verified at any point in the lifecycle of a product through independent third-party testing.

- Each pound of Repreve® polyester fibers saves the energy equivalent of 0.4 gallons of gasoline with fewer chemical by-products created in the recycling process vs. production of virgin polyester.

- Their characteristics in a finished fabric are close to those of virgin polyester in critical areas such as durability, hand, abrasion resistance, etc.

- The price gap between Repreve recycled polyester and virgin polyester is rapidly closing.

Cleansport NXT - The power of Organic Odor Control

Think of CLEANSPORT NXT as probiotics for your feet. This unique additive brings a natural odor control process to footwear for the first time.

Bacteria decompose organic material everywhere. Every day. They are used in a wide variety of tasks from helping with oil spill cleanups to treating sewage. All done naturally, safely and effectively.

Through extensive research and testing, CLEANSPORT NXT selected naturally occurring microbes that are effective eaters of sweat and its unpleasant by-product: odor. When introduced to sweat in a shoe environment, these microbes immediately go to work to produce a fresh smell, ultimately leaving behind only odorless water and carbon dioxide.

As important as these microbes are to creating a fresh environment, without CLEANSPORT NXT's patented process for attaching microbes to fabric, the results would be far less dramatic. By attaching and bonding up to 100,000,000 microbes per square inch of fabric, the surface finish starts to take effect immediately on contact, creating beneficial enzymes that devour and digest sweat. In fact, CLEANSPORT NXT claims "the more you sweat, the harder they work."

Surface treatment is done immediately after fabric production. It is fast, inexpensive and as beneficial to your customers as it is to the planet.

Dri-Brelle®

Faytex revolutionized the footwear industry by introducing a non-woven used for lining purposes back in the late 70s. After 35 years of experience with non-wovens, Faytex introduced their own non-woven synthetic fabric Dri-brelle. Dri-brelle is characterized by an exclusive diamond pattern, durability and moisture management properties.

Dri-Lex Weatherpruf®

Keep consumer's feet dry on the inside while wet on the outside with the Dri-lex Weatherpruf line. Technical

Dri-lex moisture management fabrics are combined with breathable waterproof films to form a complete Dri-lex comfort system.

Performance Fabrics with Technical Cooling Comfort Yarns

- Special Nylon 6.6 cooling yarn keeps wearers feeling refreshed and comfortable when the temperatures rise

- Provides maximum moisture management and breathability

- Can be utilized in many different fabric compositions

Cooling effect tested and measured by amount of yarn used in Dri-Freeze Products

Performance Fabrics with Natural Warmth Insulation Yarns

- Special Nylon 6.6 yarns with a coffee carbon that naturally captures body heat for greater warming results

- The carbon coffee in the fibers provide a natural antimicrobial property

- Provides maximum moisture management

- Coffee charcoal is eco-friendly and created by usage from waste of coffee bean shell residue*

Natural warmth insulation properties are tested and measured by amount of yarn used in dri-blaze products.

*Certain color restrictions apply because of the coffee carbon used in the yarn